Metal Laser Cutting Machine Youtube

The main component of the beam delivery assembly is the refractive mirror, which is used to direct the beam in the desired direction. The reflector is usually protected by a protective cover, and a clean positive pressure protective gas is introduced to protect the lens from contamination.

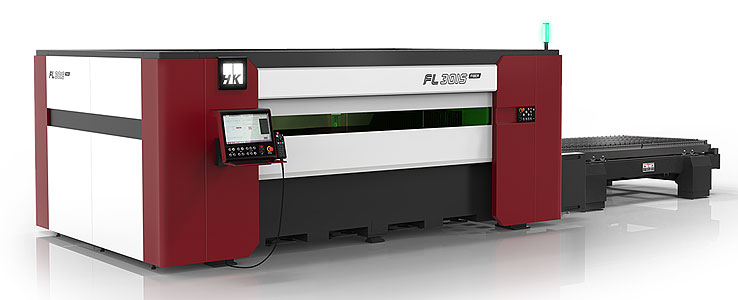

Based on the size of your table, laser cutting systems can be divided into handheld, portable and small laser cutter tables. To ensure the table fits in your space, measure it before you buy.